The Concrete Coring Pros

Eastern Cutting Corp. provides commercial core drilling services in New York, New Jersey, Pennsylvania, and Connecticut. With over 50 years of experience, you can trust our professional core drilling contractors with your commercial concrete coring projects.

In the world of commercial construction, concrete core drilling is an essential service. Drilling core holes is required for everything from building sewer systems to running telephone lines to structural testing. Coring is used in common commercial applications for installation of HVAC systems, drainage, electrical and more.

Core drilling is necessary whenever a hole is required - whether that’s on a floor, celling, door, foundation, or even a manhole in the street.

What is Concrete Coring?

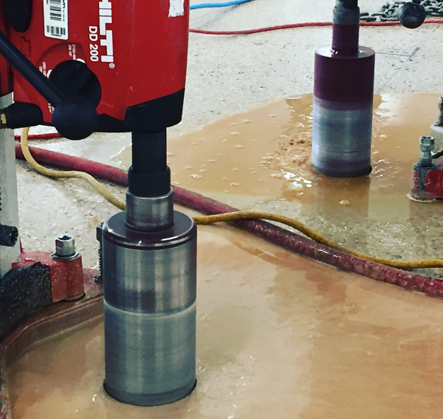

Concrete coring is the process of drilling perfectly round holes through hard structures such as concrete walls. It’s the go to concrete drilling technique when a precise circular penetration is needed.

With coring, holes up to 60" in diameter can be drilled to virtually any depth. It can be done in slabs and walls, on any angle (vertical, horizontal and even upside down!). Electric or hydraulic drilling rigs can be used for drilling in sensitive locations or confined spaces.

What are the Advantages of Diamond Core Drilling?

Diamond core drilling, named after its diamond bit, is an efficient and accurate method of drilling a wide variety of hard materials—including, but not limited to, asphalt, masonry, and steel—without vibration. No vibration ensures that nearby structures aren't damaged in the coring and drilling process. This dust-free, noise-free system makes diamond core drilling the technique of choice for environmentally-conscious concrete contractors.Diamond Stich Drilling

Stitch drilling is a common technique used to make non-standard shaped and sized holes, when standard cutting equipment isn’t suited for the job. This technique is performed by coring a series of overlapping holes, allowing for one large segment to be removed. Stitch drilling is often the answer when dealing with relatively thick slabs or walls, or when the structural integrity of the purposed opening cannot be compromised.Applications for Commercial Concrete Core Drilling:

- Plumbing for Retail

- HVAC

- Electrical

- Telecommunications

- Anchoring Bolts

- Concrete Sample Analysis / Core Testing

- Many more…

Advantages of Diamond Core Drilling

Diamond core drilling is a cost-effective cutting technique that decreases both time to project completion and labor costs. Other advantages include:

- No-to-low noise pollution

- Precision cutting through nearly any kind of material, including concrete

- No vibration means no damage to nearby structures

- An environmentally-friendly, debris-free system

- Cost-effective

History of Diamond Core Drilling

We all know that diamond core drilling is a revolutionary, cutting edge technology essential to the construction industry as we know it. But did you know that it originated in early Egypt? That’s right. Ancient Egyptians used diamonds to ‘drill’ holes into rocks used to build the pyramids. Obviously, diamond core drilling has come along way since then. J.R. Leschot, a Swiss engineer, is credited with the invention of the diamond drill in 1862. His invention ushered in an era of construction and exploration that would be unrivaled by any other technological developments in the field. While percussive drills existed at the time, the steel bits were not strong enough to drill through rock, making the process impractical and unsafe.

Diamond drilling techniques were essential to the construction of railroads, tunnels, dams, coalmines, and much more. Without it, most subterranean—or even space exploration—would not be possible. Even the Mars Curiosity Rover is equipped with a diamond drill!

-

Commercial Core Drilling Services

Commercial Core Drilling Services

-

core drilling company in nyc

core drilling company in nyc

-

Core Drilling Company Near Me

Core Drilling Company Near Me

-

Core Drilling specialists

Core Drilling specialists

-

Concrete Coring by Eastern Cutting

Concrete Coring by Eastern Cutting

-

Core Drilling Experts

Core Drilling Experts

-

Concrete Core Drilling Services

Concrete Core Drilling Services

-

Core drilling services in nyc

Core drilling services in nyc

-

Concrete Coring & Drilling Services

Concrete Coring & Drilling Services

-

Core Drilling Companies New York

Core Drilling Companies New York

-

Core Drilling Experts NYC

Core Drilling Experts NYC

-

Diamond Core Drilling NYC

Diamond Core Drilling NYC

-

NYC Core Drilling Services

NYC Core Drilling Services

-

Concrete Core Drilling Services NYC

Concrete Core Drilling Services NYC

-

Commercial Core Drilling

Commercial Core Drilling

-

Concrete Core Drilling NYC

Concrete Core Drilling NYC

-

Concrete Core Drilling

Concrete Core Drilling

-

Concrete Cutting Core Drilling

Concrete Cutting Core Drilling

-

Concrete Cutting company nyc

Concrete Cutting company nyc

-

core drilling experts

core drilling experts

-

NYC Core Drilling

NYC Core Drilling

-

Core Drilling Services

Core Drilling Services